The Laptop Refurbishment Process: Step by Step

Introduction

Having a laptop refurbished gives it a second life, and provides a cost-effective, more sustainable alternative to buying new. But what exactly happens behind the scenes when a laptop is reconditioned? This article walks you through the full process — from collection and inspection, through component renewal and software setup, to final quality assurance and packaging. Understanding this helps you trust the product and appreciate the value and effort behind a refurbished laptop.

1. Collection & Initial Intake

The first step begins when used laptops arrive at the refurbishment facility. They may have been returned from corporations, come from trade-in programmes, lease expirations, or end-of-use consumer devices. At this stage: • Laptops are logged in, serial numbers noted, and condition recorded (cosmetic scratches, dents, missing parts). • Devices are graded preliminarily (e.g., Grade A, B, C) depending on their condition and expected refurbishment effort. • A decision is made whether the device is eligible for refurbishment or should be recycled directly (if too damaged or obsolete).

2. Data Erasure & Security

Before any hardware work begins, it's critical to wipe out any existing user data and ensure security. Data-erasure protocols must guarantee that no previous personal information remains. For example, DoD, HIPAA and NIST 800-88 compliant data wiping is applied. Key tasks: • Remove or wipe hard drives/SSDs via certified software tools or physical destruction if necessary. • For laptops where drives remain, use software to securely overwrite all data. • Log the data erasure process, provide certificate of destruction if needed. This step ensures the refurbisher protects both previous users' privacy and the new user's confidence.

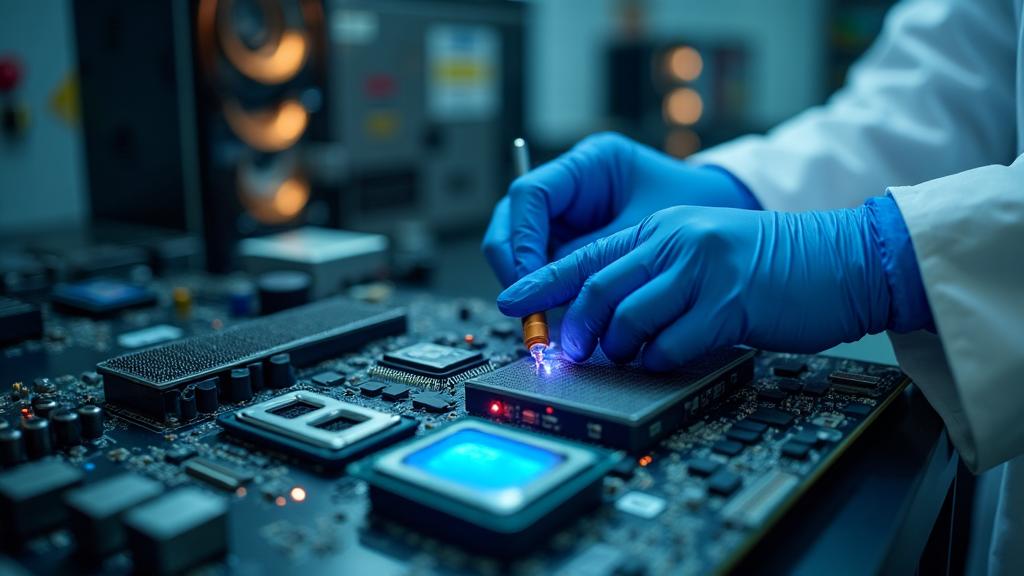

3. Disassembly & Inspection

Once data is cleared, the laptop is disassembled to enable inspection of internal and external components. Detailed actions: • Remove the battery, hard drive/SSD, RAM, covers, keyboard, display panel and other modules. • Inspect for physical damage: cracked screens, missing screws, broken hinges, port damage. • Test the battery health, look for bulging, leaking, or old cells. • Inspect cooling system (fans, heat sinks) for dust, wear or failure. • Check other components: connectors, audio jacks, USB ports, WiFi module, etc. • Separate units that cannot be economically repaired (these go to recycling streams). This step gives a clear map of what repairs or replacements are needed.

4. Cleaning & Cosmetic Restoration

With the laptop taken apart, cosmetic restoration and cleaning are carried out. Tasks include: • Use compressed air and vacuums to remove dust and debris from fans, heat sinks, internal boards. • Clean the keyboard, trackpad, ports, screen bezels, and outer casing. • Polish or replace outer shell if heavily scratched or dented. Sometimes re-painting or refurbishing the case is done for high-grade devices. • Replace worn key caps, hinge covers, or any part that negatively affects appearance or feel. • Re-install thermal paste if necessary, ensuring optimal cooling performance. This step ensures the refurbished laptop not only functions well, but also looks presentable and professionally restored.

5. Component Repair & Upgrades

This stage involves replacing or upgrading hardware components. Focus areas: • Battery: Replace if capacity is significantly degraded (e.g., holds less than 50-70% of nominal). • Storage: Replace old HDD with SSD or at least test existing drive and replace any that fail diagnostics. • RAM: Upgrade or replace faulty memory modules to meet a defined minimum specification. • Motherboard/CPU/GPU: If major failure, decide if economically repairable. • Display: Replace cracked or burnt displays, fix dead pixels, adjust backlight. • Cooling system: Ensure fans and heat sinks operate correctly; replace if faulty. • Ports and connectors: Replace broken USB/HDMI ports, re-solder or replace as needed. • Operating system license: Ensure genuine OS is installed or transferred. In many refurbishment operations, upgrades (e.g., adding SSD, more RAM) are offered as value-adds for customers who want better performance.

6. Reassembly and Firmware/Software Installation

Following hardware work, the laptop is reassembled. Next, software steps are taken: install or re-install the operating system, drivers, firmware updates, BIOS upgrades, and run initial tests. Key software tasks: • Install a clean, properly licensed copy of the operating system (Windows, Linux, etc). • Install all required drivers for hardware components (chipset, display, WiFi, audio). • Apply latest BIOS/firmware updates to manufacturer specifications. • Update OS to current patch level and secure the system against vulnerabilities. • Remove any residual bloatware, previous user software, and ensure system is clean. • Set up factory or vendor-defined settings and user account structures. • Set up basic utilities (battery monitoring, diagnostic tools) if part of refurbisher's offering.

7. Functional Testing & Quality Assurance

Before a laptop is released for sale, it must pass rigorous functional testing and quality assurance (QA). Testing criteria include: • Boot-up time, system stability under load (stress tests). • Component tests: CPU temperature under load, GPU if applicable, memory throughput. • Battery charge/discharge cycles to validate battery health and runtime. • Display tests: dead pixels, colour accuracy, brightness uniformity, hinge durability. • Input tests: keyboard, mouse/trackpad responsiveness, touch-screen if applicable. • Port functionality: USB, HDMI, audio jack, Ethernet, WiFi/Bluetooth connectivity. • Sound and speaker tests, microphone if present. • Thermal behaviour: the laptop should not overheat or throttle under load. • Cosmetic inspection: exterior should be clean, no missing screws or loose panels. This step ensures you, as the end customer, receive a device that is reliable, safe and fully functional.

8. Grading, Certification & Warranty

After testing, the device is graded for condition (for example Grade A – minimal cosmetic wear, Grade B – moderate wear, etc). Some refurbishers provide a certificate of refurbishment and offer warranties (e.g., one year). Elements to highlight: • Device documentation: serial number, date refurbished, test logs, any replaced parts. • Grade label: will help the buyer understand the cosmetic condition and possibly pricing. • Warranty period: typical refurbished laptop warranties range 6-24 months depending on provider. • Return or repair policy: Provide after-sales support to purchaser. Certification signals that the refurbisher stands behind the quality of the device — an important trust factor.

9. Benefits of the Process

Explaining the process helps highlight key benefits: • Extended lifespan of devices — fewer new units produced means lower environmental impact. • Cost savings for the user: refurbished laptops typically cost 30-50% less than new equivalents. • Assurance of reliability: with proper testing and warranty, refurbished devices can match new. • Sustainability and reduced e-waste: Devices diverted from landfill and reused. • Opportunity for upgrades: Some refurbished units come with enhanced specs (SSD, more RAM) which enhance value.

Conclusion

By understanding the step-by-step process of refurbishing a laptop — from collection through to final hand-over — you can appreciate the value behind a refurbished device. For our e-commerce site, this explanation builds trust with customers: we're not simply selling a used laptop, but a product that has undergone a rigorous renewal process to deliver reliability, value, and environmental benefit. We invite our customers to explore our refurbished stock knowing they receive a device restored to high standards, backed by warranty and sustainable practice.